LPP Carbon Prop Spar

By Mike Kirda

Recently I built a Limited Penny Plane to compete in the Bong Eagles contest. I’ve been pretty hard on LPP props in the past – Racine Memorial Hall’s ceiling is quite scrubbable, but I still broke my fair share. Determined to avoid this, I built a very robust prop spar: 7# balsa, 0.125″ center tapered to 0.080″ tip.

On my last flight of the day, the plane hit a railing and broke the prop spar while walking down the wall. It was centered on an open door and flew into the next room where many contestants were set up. All had a good laugh as my ‘Korda Wakefield’ continued to bang around the ceiling just out of reach for the next couple of minutes.

I wasn’t very happy to be honest – I kept thinking “Stupid Spar”. I thought back to Kang Lee’s Carbon VP hub and the carbon tube it used and wondered how well it would work…

The carbon tube is very strong and the blades needed less support than I imagined. I built a couple of new props using the carbon tube, trying them out at the next flying session and they worked very well.

One bit about carbon: Be careful around the dust. I use a vacuum to keep it down, plus use a particulate mask if cutting it indoors. Outdoor might be a better option. All cuts are made with a Dremel and diamond cutoff wheel.

To make the carbon spar, cut a length of 0.039″ carbon tube ~4″ long.

Alternatively you might just want to drill the hole 2″ from the end of the tube before cutting it off. This way if you goof up, you only lose 2″ instead of 4.

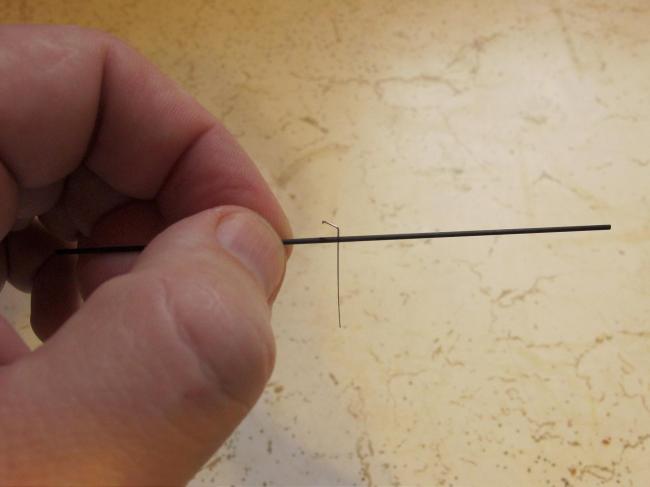

A bit of experimentation on length here might be best. At the center, drill a hole through using a #80 drill bit on a drill press. This fits a 0.013″ prop shaft perfectly. Alternatively a #78 or #79 bit should work if you want to use 0.015″ music wire instead.

The best way to drill the hole is to lock the tube tightly into a 0.040″ slot.

You can purchase a router bit this size and feed a bit of wood through a router table (or drill press very slowly) to get the slot cut. Alternatively a bit of 1/16″ ply base with some 1/32″ ply to make a 0.040″ gap would work.

Next I drill another hole about 1/8″ away from the center, drilling just to the center of the tube. You can bend the prop shaft over to go into this hole. A bit of Kevlar thread and glue will bind it together. Just add a Teflon washer and rubber hook to your liking.

Next put the the spar into your prop pitch fixture. Add glue (Ambroid) directly to the carbon tube, then put the blade on top. Quickly tape the blade in place with blue tape. The spar may also be taped to the underside of the blade. Let dry completely, then check the pitch. Sometimes the glue shrinkage will change the pitch. A bit of acetone to loosen it, twist a bit more in the opposite direction, then let dry. Keep at it until you get it right. Adding plasticizers to the glue may help.

CST or ACP will carry the 0.039″ carbon tube. You may be able to order through a local hobby shop.

Orange balsa??? it’ll never catch on!